If you have ever walked into your hallway or laundry room only to find your Litter Robot mid-cycle with a blinking red light displaying a pinch detect fault, we already have something in common.

Just like you, I found myself in that exact scenario on a particularly cold morning with a work call scheduled in twenty minutes and my cat Noodle had just used the unit.

I felt a knot tightening in my stomach when the dome remained static mid-spin, the indicator light blinking like some form of technology warning me of a malfunction. I felt no vacuum, cat litter box, or appliance meant to make my life easier had the right to break down at that moment.

The text error was quite alarming as well. I had never seen that specific error before and from a distance, it seemed quite serious suggesting some blockage or a foreign object inside the unit, or worse—it was broken.

What made it worse was how unresponsive it was—ignoring every button I pressed as if in a form of defiance akin to a teenager lost in their music.

Key Takeaways

- The pinch detect fault normally means the sensor plates are dirty or blocked.

- Restoring function begins with the electrical disconnection, mechanical inspection, and careful cleaning of the device.

- In the case of a reset function, prior visual confirmation of alignment and proper contact is critical.

- If resolving an issue is unsuccessful, inspecting the cabling is necessary, and technical support can be contacted if required.

- Avoid problems by performing weekly maintenance; the machine appreciates routine.

What The Pinch Detect System Is Supposed To Do

Before troubleshooting the fault, I had to ascertain its meaning first.

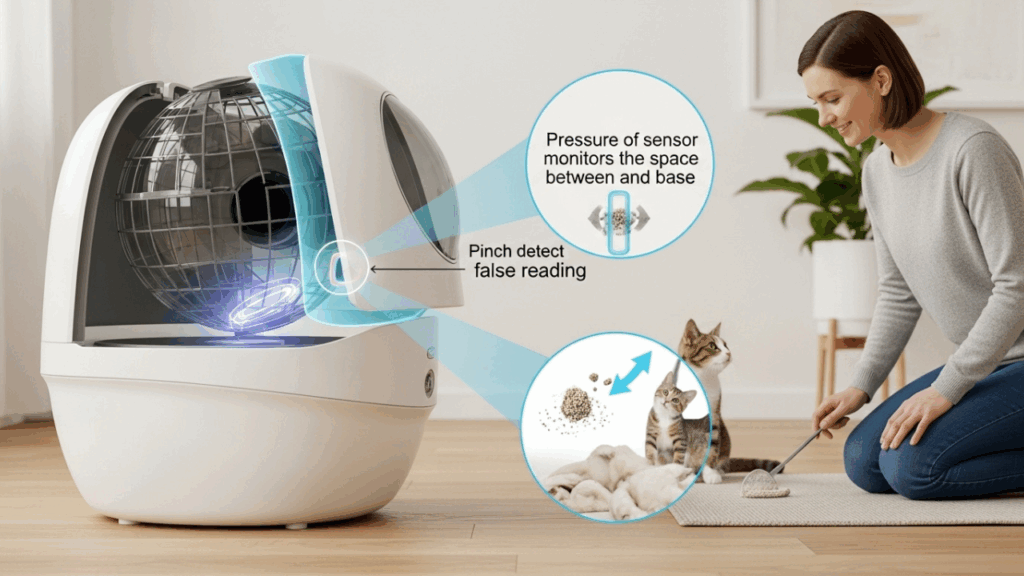

To determine whether an obstruction is present between the globe and the base section of the Litter Robot, a pressure sensor is employed. This sensor acts as a safety mechanism which, quite frankly, I find valuable.

This is because it prevents the motor from damage and ensures that your cat will not be harmed if something gets stuck while the unit is cycling through its processes.

Like any other smart system, it can make erroneous readings from signal inputs. A bit of Litter, a misplaced component, or some compacted dust can be enough to confuse the system’s smart sensors. That is precisely what I was working with and maybe that is what is happening to you as well.

The First Time I Got It Wrong Before I Got It Right

For context, the beeping and the motor cycling of the LitterRobot was the issue that I was facing. And from what you have told me, there is no inherently ‘wrong’ way of working with the device. The problem, however, stems from a lack of understanding of the problem domain. Jamie, the very first thing that I did for resolving the issue was to reset the device. I tried resetting it multiple times and even turned off the power multiple times. But every single time I encountered the same result.

As I said earlier, my first set of actions led me down a specific route that didn’t solve the problem to being inefficiently trying to solve the problem. This is why I took more of an inquisitive approach in which I sat down and carefully examined the device. During this process, I reasoned that for a pet owner, their wellbeing is greatly intertwined with this device.

What Usually Causes The Pinch Detect Fault

The techniques I used revealed to me that the most frequent issue stems from a minimal accumulation of litter, dust, or possibly moisture on the pinch sensors within the base. Those two contact sensors are situated exactly where the globe joins the bottom frame, and they can accumulate grime over time. That grime causes a trigger malfunction by simulating pressure on the sensors when no pressure is applied as rotation occurs.

In my scenario, it wasn’t just one thing, but rather a combination of multiple factors. A combination of some damp litter clustering to one side, and the globe not being perfectly seated after my last thorough clean was the problem. The sensor plates being dusty did not help either. In this case, it looked to the machine as if something was blocked in the path of motion, thus it halted operation as a safety measure. The positive outcome is that the motor was not burned out. The downside is that I still had to undertake repairs.

How I Actually Fixed It And Got The Unit Back To Normal

Jamie, I will explain how I solved the issue and hopefully, you can do it too. There was no need for any specialized equipment or technologies. To begin, I completely unplugged the Litter Robot. Afterwards, I carefully detached the globe and put it to the side. I utilized a dry microfiber cloth to clean the pinch sensor region, which is the small area inside the base adjacent to the metal contacts. I was cautious not to apply any water or cleaning solutions to this area since I did not want to put any components at risk.

I ensured that the globe was completely dry and that no loose debris was caught at the lip or edges. Then, I refitted the globe, making sure to observe how it aligned with the tracks. I manually turned it bit by bit to check for any friction or noise prior to plugging the unit back in. After confirming everything was functioning smoothly, I plugged the unit in and observed.

At this point, the light blinked once. The globe completed a full rotation and came to a stop precisely at the expected position. The red light indicating the pinch detect fault was also gone. I stood there quietly triumphant as Noodle examined the globe as though I had done something deserving of her approval.

When The Fault Comes Back Anyway

Sorry Jamie, not all solutions work on the first attempt. A few weeks after, the same problem started repeating itself. I felt that old frustration creeping in—but I had a plan. I followed the same steps, but this time, I went a little further. I checked if the wires at the bottom of the base were snug. I only needed to tilt the base and see whether everything was in order.

That was partially problematic. This approach overlooked verifying if the connections were certainly secure. The approaches I did led to the right solution. The second fix was much more effective. Self inspections of systems reached a new level. In particular, the habit of weekly checkups gained traction. To my surprise, the system operated smoothly for an entire week.

Understanding That It’s A Smart Machine With Dumb Sensitivity

One thing I have come to terms with is that the Litter Robot is smart—but not without its discrepancies. The way its sensors function is through resistance and contact logic. They do not interpret signals—they simply react to them. Therefore, a small override could cease the entire process. This is the reason why cleaning and alignment are so pivotal. That is why I always tell friends who use it: view it as a helper, not an all-knowing machine. It relies on you just as much as you rely on it.

When To Call Support Instead Of Guessing

There exists a boundary where home repairs may become insufficient. If you have done a complete system check by cleaning the sensor, resetting the unit, checking the wiring, and the fault persistently occurs after every cycle, it is best to seek assistance from Litter Robot’s support team. They have seen everything. And if your device is within the warranty period, there are chances they will send you a sensor replacement or base swap.

The most important aspect is keeping track of what you have done so far. If possible, capture a few photos or record a short video of the problem you are trying to solve. Explain every action you have undertaken. Your description does not have to be lengthy; concise descriptions will do the job, but it will aid in expediting their analysis. In my experience, the responses I have gotten were not generic. They were tailored to the problem I was presenting, and they offered sincere assistance.

What I Do Now To Avoid This Fault Altogether

From the beginning, Jamie, I’ve altered my maintenance routines related to the Litter Robot. For example, every Sunday, I clean the sensor plates. I check that the globe clicks into place as it should. I do not exceed the maximum fill line for litter. Finally, I keep the unit on a flat, stable surface so the unit does not shift during cycles.

These small changes transformed the pinch detect fault from a recurring nightmare into an infrequent and easily fixable hiccup. And beyond that, these changes increased my confidence. Because nowadays, when something goes wrong, I understand the diagnostics and the corrective actions necessary.

My Opinion

If I may add, if you are reading this while your Litter Robot is motionless in the corner with a red light blinking, while your cat glares at it as if it has committed treachery, I want to assure you that you are not alone. That error message does not spell doom. It is merely a signal. A gentle prompt. An invitation to offer assistance. And now, you have all necessary steps to provide the assistance needed.

There is no requirement for you to be a technician. All you need is a cloth, some patience, as well as a willingness to lend an ear to your machine and appreciate what it is trying to communicate. When that light goes off and the globe spins clean again, you will feel what I felt—a strange pride knowing you did not just own a smart device, you understood it.

RapTijd

RapTijd