Lets go ahead and start this thing, buddy. Remember the last time you spotted a little robot gliding around and picking up a plastic cup as if it was made of silk? Slide out the flashy decals and one piece does nearly all the heavy lifting. Were talking motors, those unassuming metal guts tucked way inside. No press conference ever invites them on stage, yet yank a motor out and your trendy bot turns into an over-priced paperweight.

I promise well pry open the mystery of how motors tick, peek at the latest write-up in The New York Times, and maybe even spot why any of this should matter when you head to school tomorrow. Spoiler alert: that same small whirring device is already yanking invisible strings in dozens of gadgets you own without asking for credit.

Key Takeaways

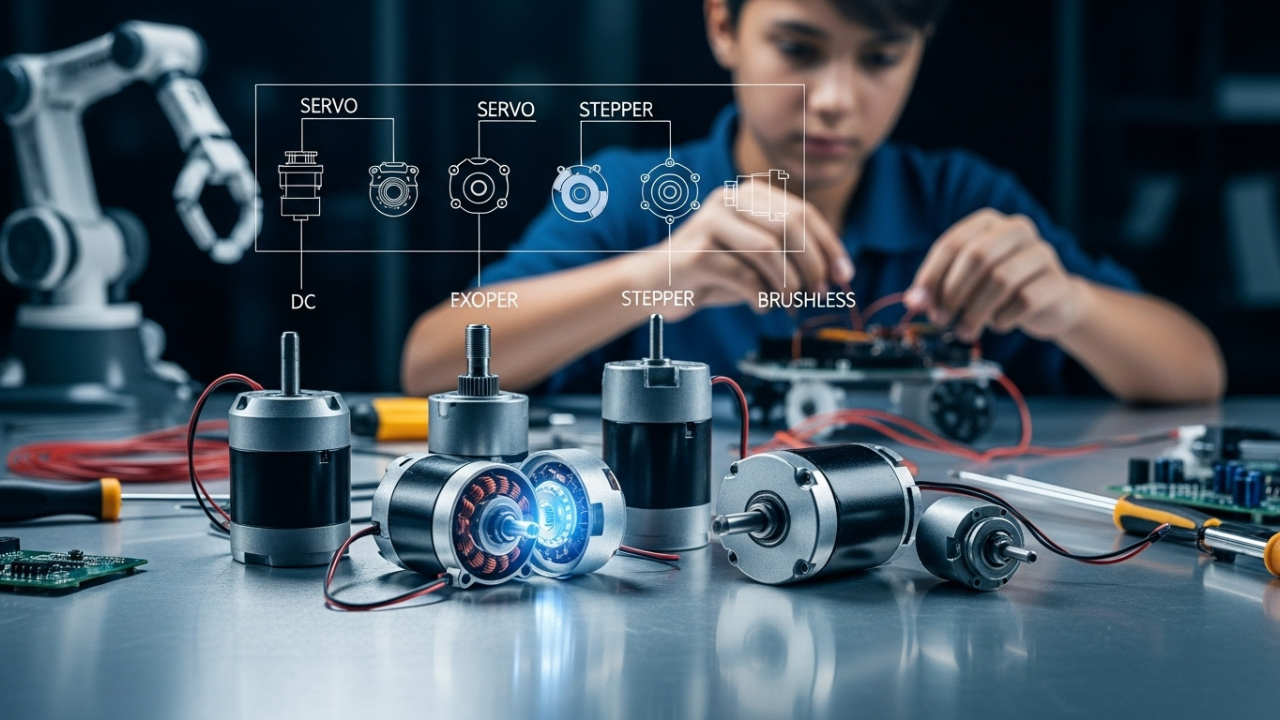

DC, servo, stepper, and brushless motors each have their own playbook when it comes to moving machines.

Choosing the right motor is a messy chart problem of speed, muscle, size, and, yes, your budget.

The Times piece showed concrete examples of motors powering delivery drones, warehouse hands, and even a couple of kitchen toys.

Flip the remote for your electric toothbrush and you find the same tiny workhorse that keeps lab robots steady on night shift.

Learn the basics of these motors and, just like that, modern gizmos stop looking like magic and start behaving like logic.

The Heart of Movement: Motors Explained Simply

Every active machine, whether tiny or lumbering, needs a nudge to keep it cruising. Slip a motor inside, and youve more or less strapped on a set of electric biceps. The gadget never daydreams, never weighs options. One tiny pulse flips the switch, and the shaft starts twisting like it just downed an espresso.

Picture a robot vacuum sneaking under the couch, or a factory runner hefting crates; in each case, a motor chews the workload. Normal muscles tighten when the brain fires a command. A robots muscle wire reads the same order, but the signal travels over copper lines, not spinal cords, and the tissue is solid metal rather than rubbery flesh.

Not long ago the folks over at The New York Times dove into motors-and-robots. They told a story that felt less like a gadget list and more like a neighborhood watch announcing how machines are quietly learning tricks. Speed, smarts, and extra helpings of precision sat at the dinner table, while different kinds of motors played the role of invisible chefs.

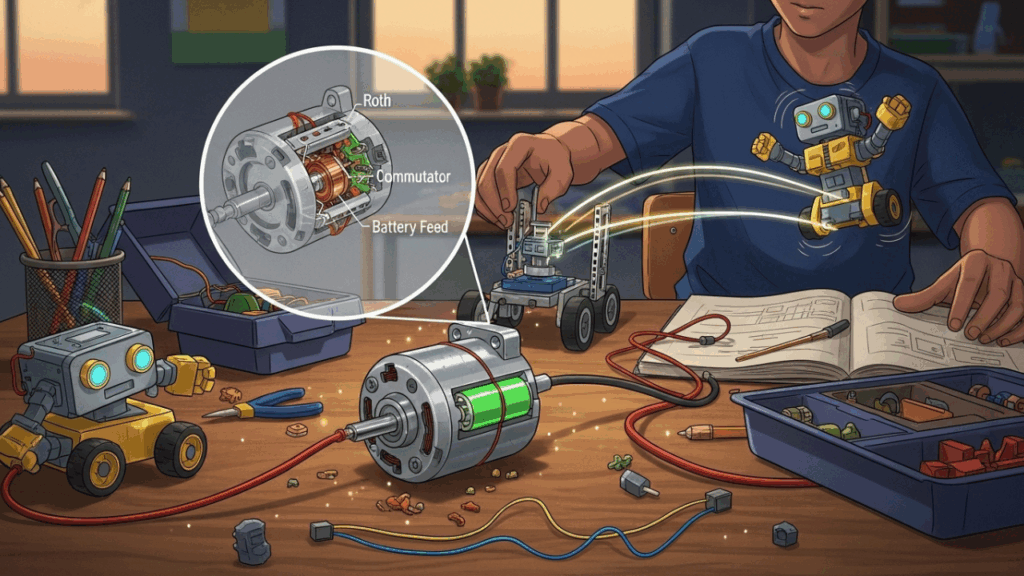

The Quiet Power of DC Motors

Flip the page and you land on the humble DC motor. Its neat, buzzing hum shows up everywhere-on classroom workbenches, inside toy robots that zoom across the carpet, and even in the earliest hobby kits kids tear open after school. The name Direct Current hints at the steady juice it munches from a battery.

Turning fast is its party trick, and it answers commands almost before you blink. Precision? Well, sometimes it acts more like a toddler than a surgeon. Parts wear out if you push too hard, yet those tiny quirks make it the perfect pair of training wheels for any robot that needs to learn how to roll, spin, or just scoot across the table.

Servo Motors and the Art of Control

A DC motor is like a kid on a bike, full of energy but steering with their knees. The servo, by contrast, is a race car glued to the asphalt, heading exactly where the driver points. Give a servo the command to crank to thirty degrees and it snaps there, holds the pose, then freezes until you yell again. Picture a robot reaching for your favorite mug; the arm bends just enough, never too far, never shy.

That little bit of magic is the servo doing what it was born for: quiet discipline, razor-sharp control. Slip one into the joints of a camera gimbal or the belly of a drone and it whispers precision to every axis. The New York Times piece on da Vinci-style surgical robots? Odds are a whole choir of servos was wiring the scalpel moves before the ink was even dry on that page.

Stepper Motors: Walking One Step at a Time

Picture a 3D printer as it coughs out plastic layer after layer, screaming hurry-up but moving at its own tempo. It could be a metronome counting away, hitting one beat at a time, never skipping, never rushing. That metronome behavior is the stepper motor to a T; no endless spin, just tiny, locked-in slices of rotation. Each mini-step is a promise kept, so even if the whole job takes hours, accuracy never snoozes. If a DC motor is a wild mustang, the stepper is the chess player staring at the board, measuring seven moves ahead.

Makers who crave precision swear by stepper motors because, honestly, they never wander off-script. Picture a pencil drawing exactly what you want, again and again; these gadgets do pretty much the same thing with gears and pulleys. The New York Times recently spotted them glued to factory bots assembling everything from phone innards to those clicky little watch gears we sometimes lose on the floor.

Brushless Motors for the Long Run

Zip over to the world of brushless motors if youre after speed without the static roar. They hum, not grind, and that single difference lets builders stash one in a drone today and yank it out of a twenty-year-old electric car tomorrow. In the brush-happy designs, metal contacts scrape against metal, creating heat and throwing tiny sparks-sometimes called wear debris. Skip that drama and you gain longer life, simple as that.

Because the design keeps everything tidy, people who run factories where downtime costs real money roll these motors onto almost every assembly line. The folks quoted in the Times pointed out that the built-in circuitry lets the motor sip power or chug torque whenever the job shifts, almost like a driver shifting gears instinctively. Smarter, quieter, and less needy for wrench time; in the race for reliable machines, brushless is pretty much waving the checkered flag.

How Engineers Choose the Right Motor for a Robot

Okay, let me ask you something big: how do engineers actually choose a motor? They don talk wild guess-no way. First, they stare at the robot size. A build yanking steel sheets definitely needs more brawn than a little helper sweeping crumbs off your counter.

That brawn is what torque measures, how much twist a motor can dish out. Next pops up speed; some machines zoom around, others tiptoe like theyre in a library. Precision tags along too-does the robot have to click to an exact 90-degree stop, or can it just whirl and hope for the best?Each of those whys points to a different motor family.

Cash, of course, pokes its nose in. Slam-bang cheap parts break apart after lunchtime, while tough-guy motors will gladly take your paycheck. Dust and heat throw another wrench; anything grinding or frying on the job has to wear armor, even if that armor costs a pretty penny. Power draws the last line in the sand; beefy motors suck juice like a toddler at a juice box, and that really hurts a battery-powered robot trying to win the long haul. Picking this gadget is a bit like slipping on the right pair of sneakers for gym class:not too tight, not too loose, or youll be limping before the bell.

What the New York Times Highlighted in Their Feature

When The New York Times picked the piece, it skipped the usual gadget geek talk and zeroed in on real-world muscle. The headline motors are giving companies the kind of lift you cant get from coffee alone. Take a busy shipping wharf where a squad of silver robots zips down the lanes, nudging pallets, stacking crates, and pausing politely for the human crew.

Those little workhorses jam together three motor styles- stubby DCs for turf, tight-loop servos for elbow agility, and whisper-quiet brushless spins that keep the whole parade steady. The piece finished with a snapshot of a warehouse aisle where a jumper-clad woman high-fives a blinking LED eye, each partner finishing the other.engines humming, human smile.

One chapter of the piece kicked off with hospitals. Carts no bigger than a suitcase now glide down corridors, arms extended like a waiter presenting a tray. Doctors lean in, watch a wrist-sized claw hold a scalpel in a perfect tilt no human could hold for that long. The motors hidden inside-those tiny precision engines-steal the spotlight without anyone intending to. Surgeons still call all the shots, yet it feels as if each operation has a second, almost tireless apprentice.

Where You See These Motors in Daily Life

You might blink and wonder where those engines turn up when youre off campus. Surprise: theyre already invading the ordinary. Your fetching little floor robot whirrs beneath the couch and spins on a dime thanks to a brushless motor that hums louder than a mouse but softer than a cat. The whisper of a DC fan inside your smart speaker keeps the chipset cool while you meme.

A cylindrical delivery bot trundles by, steering on the fly with a cocktail of stepper and servo motors only courier nerds notice. Even that drone circling above, sending kid-at-heart snaps to its owner, survives off brushless motors that sound as fierce as a swarm of bees yet handle like a camera on a calm day.

This isnt tomorrows sci-fi; its whats charging your lunch right now. Without the motors-those unglamorous workhorses-none of it would budge, blink, or bother moving at all.

Looking Ahead: Motors Building Tomorrow’s Robots

Robotics keeps racing ahead, and the little electric hearts inside those machines are getting a tune-up of their own. Soon the same motor you might find in a hospital delivery bot could fit inside your favorite toy yet lift four times the weight.

Doctors picture a robot gliding through narrow hallways with a tray of medicines, while farmers dream of arms that gently twist ripe peaches without leaving a bruise. Even quiet space explorers need motors that think two moves ahead. Industry pros quoted in the Times now say the best motors will pack in their own sensors, software, and safety checks the way a phone crams in apps.

Picture a tiny motor that notices it has overheated, cooldowns on its own, and texts a maintenance crew before a single wire burns. Envision another that learns every time it hoists a load and quietly trims its energy draw so the battery lasts all day. Researchers insist were closer than most of us realize. The headlines may sound like gadget fluff, yet they mark the day motors-no louder than a refrigerator fan-stopped hiding in the shadows.

My Opinion

So here it is, plain and simple: whenever you spot a robot-scouring a floor, zipping through an airport, or maybe even hovering like something out of a comic book-some hidden piece is already sweating the details. Spin a shaft, yank a gear, or just freeze in place for the tiniest beat. A pile of motor types sits backstage, waiting for orders. Sneak a peek at a DC unit if you want speed. Find a little servo when grip and angle matter. A stepper counts steps like a runner kept honest by a coach. Brushless variants hum along, keeping the noise down while the rest earn the spotlight.

Call them by name or toss the labels aside; the goal remains the same. Motors keep the show in motion even when they sit out of sight.

Give a gadget another brain or a flashier casing, and its motor quietly upgrades, too. No trophies parade past the workbench, no hashtags trail their midnight shifts-yet every wild idea on wheels owes them breakfast.

Want that next robot build or class project to pop? Trace the wires back to the motor first, because that tiny drumroll turns theory into motion you can watch.

RapTijd

RapTijd